Products Category

Contact Us

Tel: +86-18 423 717 818

E-mail: sales@cqoptics.com

Add: No. 5, Torch Ave, Jiulongpo District, Chongqing,400080 China 3rd Zone, Gongdatang, Jiangdong Street, Yiwu City, Zhejiang Province 322099 CHN

Skype: 27393442@qq.com

WeChat: Matrip023

whatsapp: +86 18423717818

Company News

>> Influence of EVA Film aging on photovoltaic modules

The chemical stability of polymer encapsulation materials in photovoltaic modules is an important factor in determining the durability of photovoltaic modules. As the main material of photovoltaic encapsulation film, EVA will affect the performance of photovoltaic modules once it ages? What are the ways to increase the anti-aging of EVA materials?

1. Faded.

During the operation of photovoltaic modules, EVA will undergo "yellowing" and "browning" when exposed to the outdoor environment for a long time. The discoloration reduces the light transmittance of EVA, reduces the photocurrent of photovoltaic cells, and eventually leads to power loss of photovoltaic modules. The main reason for this phenomenon is that the chemical composition of the EVA packaging material has changed under the combined action of damaging factors such as ultraviolet light and infiltrating water vapor, resulting in the formation of unsaturated polyolefin chromophores. With the accumulation of unsaturated polyolefin compounds , the color of EVA will gradually deepen, from light yellow to dark brown.

2. Layering.

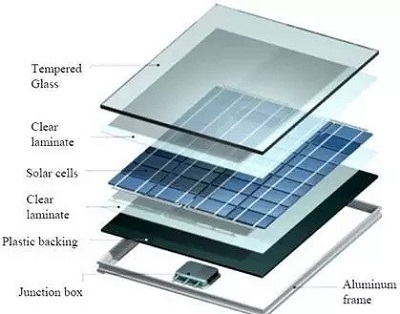

Degradation of EVA can cause its adhesion to decrease, delamination occurs, and thus the adhesion between the cover glass and the solar cell and/or between the solar cell and the backsheet material is lost. Delamination of PV modules results in increased light reflection, increased water infiltration, loss of output power, and damage to the entire system. There are many factors that lead to delamination, and the aging of EVA during use is the main reason. The aging of EVA destroys the bonding bonds at the interface, resulting in the formation of voids between EVA and other layers. In this process, factors such as light, heat, oxygen, and water play an important role. Generally, hot and humid climates will accelerate delamination.

3. Foam.

Blistering is somewhat similar to delamination, it is caused by the lack of adhesion of EVA, and the affected area is smaller. The bubbles are caused by chemical reactions that release gases that typically appear at the rear of the module and collect in the package, but occasionally appear at the front between the glass and the battery. Air bubbles often appear in the center of the battery, which is caused by the high temperature inside the battery and the different adhesion of EVA. The air bubbles inhibit the heat dissipation of the battery, reduce the service life of the components, reduce the absorption of sunlight by the photovoltaic module, and increase the reflection of sunlight.

4. Add inorganic particles to EVA material to resist aging.

Adding inorganic particles is one of the ways to improve the aging resistance of EVA. The acid-functionalized graphene nanosheets are introduced into EVA as a reinforcement, and the obtained EVA/GNP composite film encapsulates the dye-sensitized battery, which can prolong the service life of the equipment; the EVA/GO nanocomposite film is prepared by using graphene oxide. The membrane has a good waterproof structure and is not permeable to oxygen, so the anti-aging performance is improved, and the polar groups of graphene oxide and vinyl acetate groups interact to improve the interface adhesion; the rare earth Y2SiO5 : The addition of Ce3+ and Yb3+ to EVA can improve the thermal conductivity and adhesion of EVA without affecting the light transmittance and electrical insulation, so that oxygen and moisture cannot enter, thereby improving the thermal stability of the packaging material; Adding BN, SiC, ZnO and other highly thermally conductive inorganic particles to EVA packaging materials can prevent local thermal aggregation of photovoltaic modules, thereby improving the thermal stability of the modules.

5. Add auxiliaries to EVA material for anti-aging.

Antioxidants, UV absorbers, light stabilizers and other additives can reduce the oxidative decomposition rate of EVA packaging materials and improve the thermal oxygen aging resistance, ultraviolet aging resistance, and humidity and heat aging resistance. In general, the composite stabilizer can reduce the aging rate of EVA more than the single stabilizer due to the synergistic effect of each component. In addition, adding optical frequency conversion material can convert the ultraviolet light irradiated on the surface of EVA into visible light, reduce the aging rate of EVA and improve the photoelectric conversion efficiency of photovoltaic modules.

6. Cross-linked anti-aging.

Cross-linking can make EVA form a stable network structure, and appropriately increasing the degree of cross-linking is an effective method to improve the aging resistance of EVA films. There are many methods of EVA crosslinking. Organic peroxide is the most commonly used crosslinking agent. At a certain temperature, the free radicals generated by the decomposition of organic peroxides attack the EVA molecular chain, resulting in a free radical chain, and the two free radical chains combine. form a cross-linked structur

Evaporation Materials

Evaporation Materials